[ad_1]

Chemical provider LANXESS and automotive supplier Kautex Textron say they have proven the feasibility of the plastic polyamide 6 for high-voltage battery enclosures in EVs.

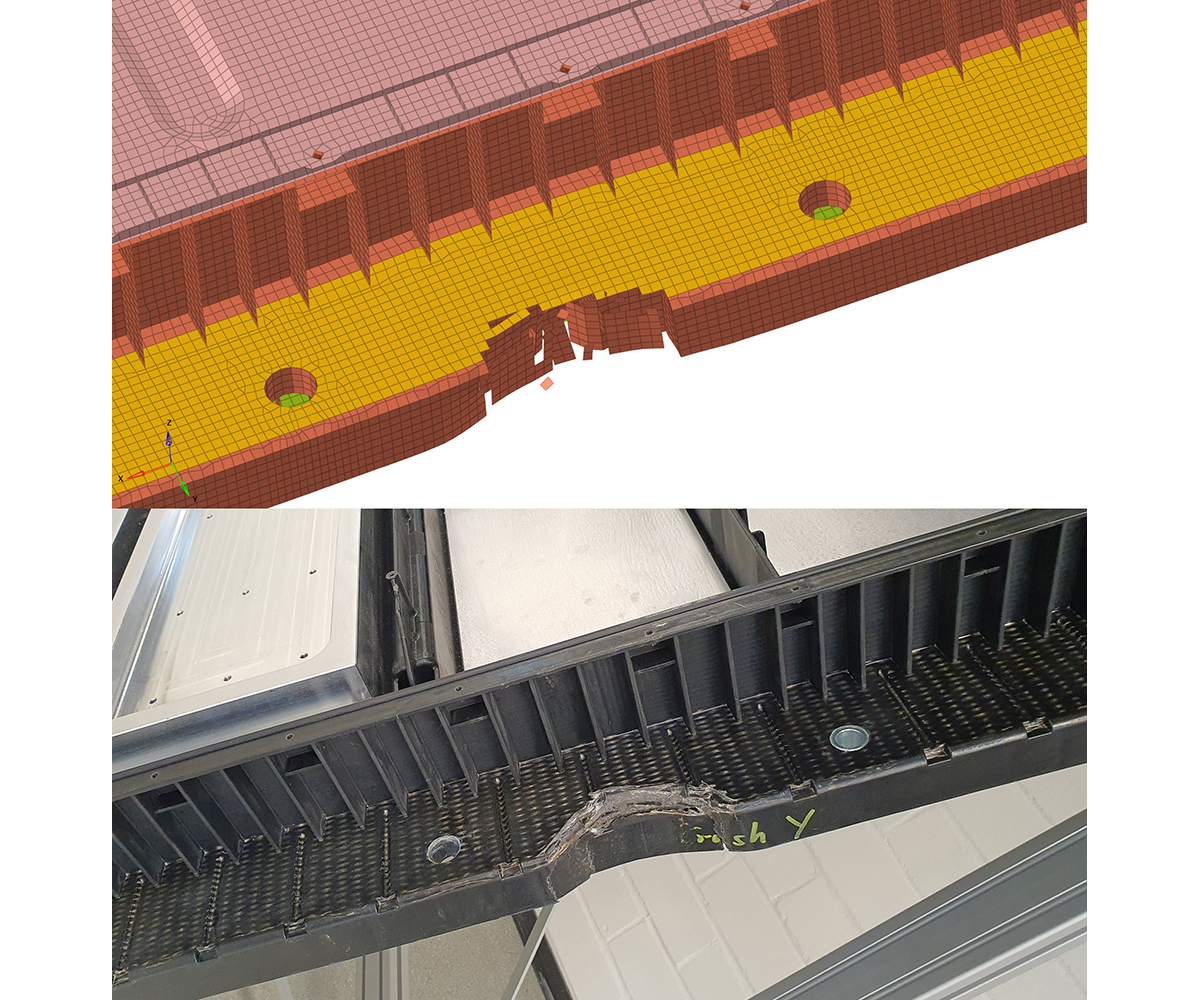

The companies jointly developed a 1.4-meter demonstrator composed of a polyamide 6-based composite called Tepex dynalite 102-RGUD600 in crash-relevant areas, along with the polyamide 6 compound Durethan B24CMH2.0. Kautex Textron engineered, designed and manufactured the demonstrator.

“Calculations revealed that the carbon footprint of the plastic enclosure is over 40 percent smaller compared to an aluminum design,” says Project Manager of e-Powertrain at LANXESS Dr. Christopher Hoefs. “The lower energy use in the production of polyamide 6 compared with metal as well as other factors—such as the omission of time-consuming cathodic dip painting to prevent corrosion where steel is used—help to minimize the carbon footprint.”

“The near-series demonstrator passes all mechanical and thermal tests that are relevant for such enclosures,” says Hoefs. “Also, solutions for the thermal management and leak tightness of the enclosure, for example, have been developed. This all has proven the technical feasibility of these safety components, which are complex and subject to high levels of stress.”

LANXESS also says “an enclosure prototype is being road-tested in a test vehicle to verify its suitability for daily use.”

“We are currently jointly tackling the first series-production development projects with automotive manufacturers in order to implement the new technology in series production,” says Director of Product Development at Kautex Textron Felix Haas.

Source: LANXESS

[ad_2]

Source link