[ad_1]

Fleet operators looking to electrify may experience a new form of “sticker shock” when they realize how much electrical power will be required to keep their vehicles running on schedule. For a fleet of any size, a charge management solution is a must to keep energy consumption under control.

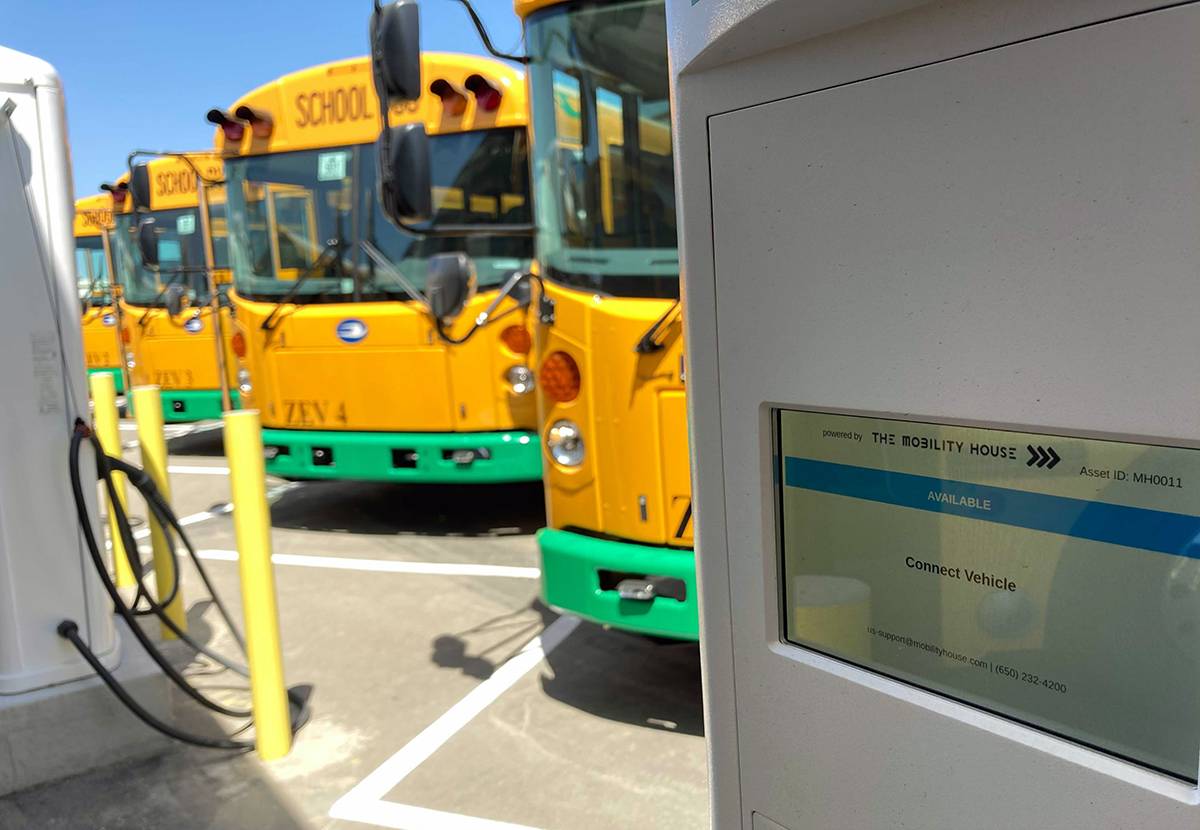

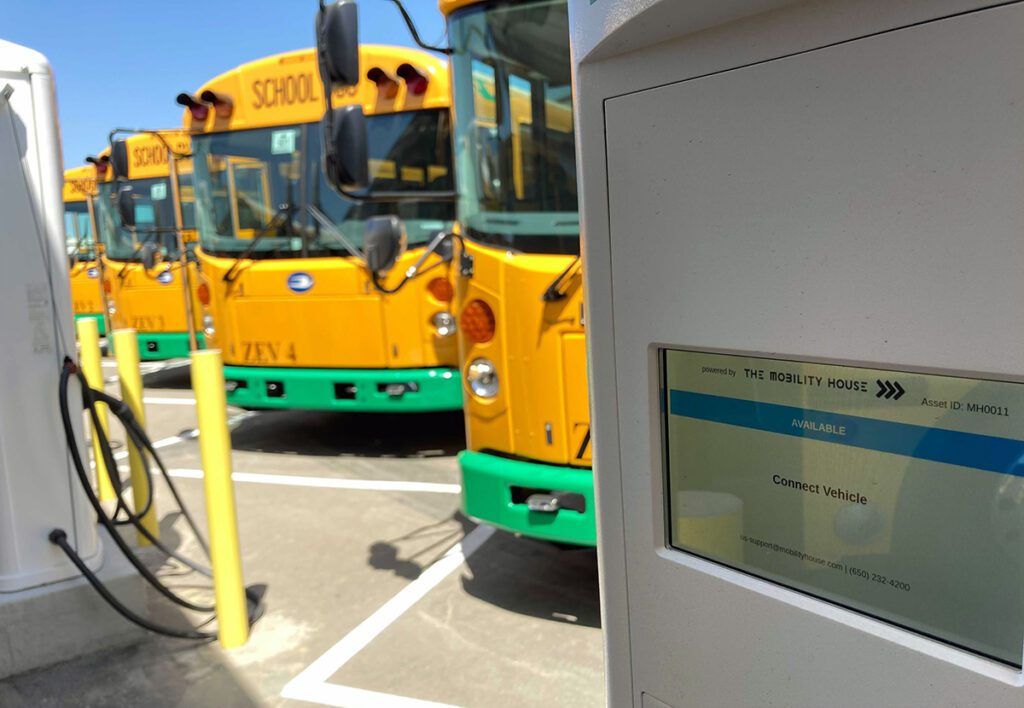

Charged asked Sam Hill-Cristol, Business Development Manager at The Mobility House, to give us some numbers. For example, let’s say we have a fleet of 50 trucks or buses. How much power capacity will we need, and by how much can we hope to reduce that requirement by using charge management?

Hill-Cristol explained that everything depends on the duty cycle of the vehicles. “If it’s a larger, mid-mile delivery truck, maybe you’re looking at a 50-kilowatt to 100-kilowatt charger minimum, and a 250 kW or even 350 kW charger could be needed. If you need that for every vehicle, you’re looking at 2,500 kilowatts, 5,000 kilowatts minimum. For school buses, often we’re looking at 19.2-kilowatt charging stations. So if you had 50 of those, that’s about 960 kilowatts.”

That’s the “nameplate” charging capacity—what you would require if you simply plugged in all of the vehicles at the same time. Of course, the point of charge management is to bring that number down.

“With charge management, we can see anywhere from a 15 to 20% reduction in that peak, all the way up to maybe 60% for school buses in some cases that we’ve modeled,” says Hill-Cristol. “School buses are a use case that has a huge potential for charge management because their schedules are not very demanding. You might be able to bring that 960 kW peak down to 200 kW, because you’re spreading that across the whole night. For commercial trucks, it may be somewhere in the middle. Then for a transit agency, where you have really demanding duty cycles, the vehicles are on the road a lot, maybe you only see a 10-15% reduction. But even then, for a fleet of 50 transit buses, you’re looking at at least 5 megawatts or something in an unmanaged scenario, so even that relatively small reduction can have some pretty big cost implications.”

Charge management is not just about reducing operating costs—thinking about it in the planning stages can save on capital investment too. “If you can reduce your peak by 50 to 60%, you’re going to save money on demand charges and reduce your electricity bill,” Hill-Cristol says. “But it also can have implications for the capital costs if you know what charge management can do for you up front. If you’re reducing your peak and maybe instead of 960 kW, you only need 200 or 250 kW, you might be able to buy fewer chargers. And if those chargers are of the type where you have 3 or 5 plugs for every power cabinet, you can still plug all the buses in. You still get 50 plugs, but behind that is less power, and that’s a lot cheaper.”

Source: The Mobility House

[ad_2]

Source link