[ad_1]

With demand for EV batteries seeing an impressive 30 percent year-over-year growth, pressure continues to increase for Automotive OEM’s and Tier 1’s to keep pace. Among the many levers you have available to ramp battery production, test coverage and strategy are one of the top 3 improvements that make a significant difference in your ability to hit time-to-market demands and differentiate yourself within the industry. While testing early throughout the battery design, development, and production process is important, performing the right tests is critical for increasing battery performance, reducing cost through improved yields, and gaining valuable insights in your battery performance amidst the evolving battery technology landscape.

Join this session at our Fall Virtual Conference on EV Engineering, where we’ll cover the top 5 techniques for analyzing lithium batteries, such as ACIR and EIS, and show you how the flexibility of NI’s platform enables performing all these tests with the same set of instrumentation while providing the ability to scale with your test needs.

Other sessions at our Spring Virtual Conference include:

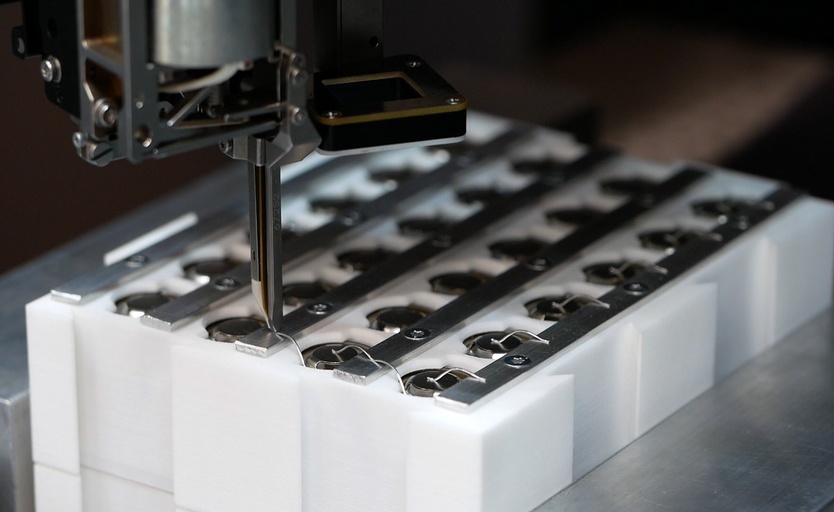

Guidelines For Implementing Wire Bonding Or Smart Welding For Battery Modules From Concept To Production

This presentation, presented by Hesse Mechatronics, will outline the necessary steps to overcome challenges when trying to get your battery module ready for production when utilizing wire bonding or smart welding technologies for cell interconnection.

Register here to learn more—it’s free!

See the full session list for the Spring Virtual Conference on EV Engineering here.

Broadcast live October 17 – 720, 2022, the conference content will span the EV engineering supply chain and ecosystem including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection, wire and cable, EMI/EMC and more.

[ad_2]

Source link