[ad_1]

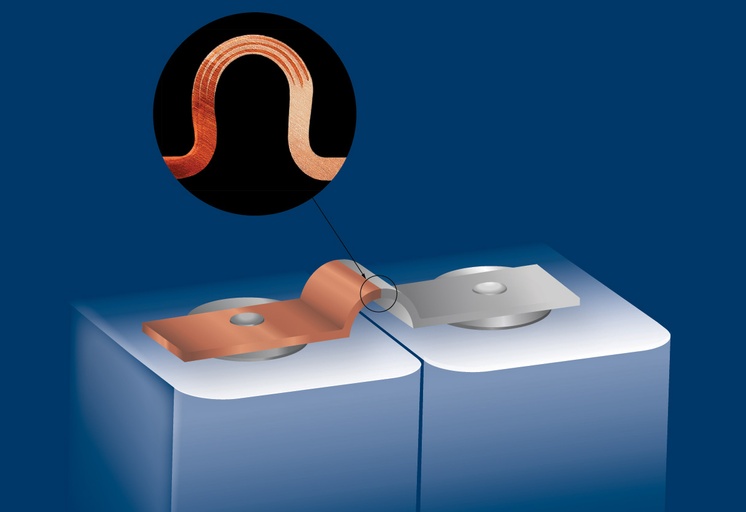

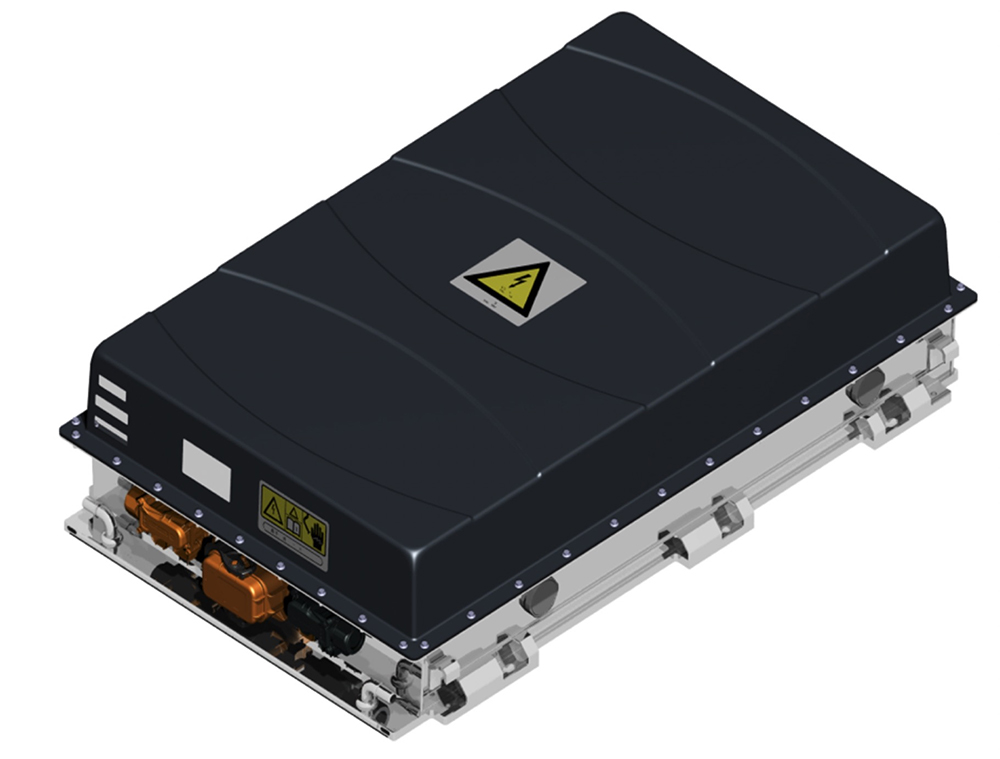

The production of electric and hybrid vehicles demands advanced materials that solve even the most difficult design challenges and perform reliably under harsh automotive conditions.

In this free webinar at our Fall Virtual Conference (October 17-20, 2022), presented by Materion, we will discuss how the latest clad metal technologies enable safer and more reliable lithium-ion packs, highly reliable chargers, and lightweight battery enclosures. Clad metal solutions offer:

- High reliability, stronger joints, and lower electrical resistance for more compact battery connection designs and unmatched electrical and mechanical performance.

- Low friction and improved wear resistance to enable longer cycle life and improved stability at elevated temperatures.

- Structural and thermal battery enclosure materials that enable higher energy density and light weighting.

Other sessions at our Fall Virtual Conference include:

Best Practices For Installing And Troubleshooting EV Charging Stations

There’s enormous demand for reliable infrastructure to power the growing number of electric vehicles on the road today. For electrical professionals, EV installations create new opportunities and additional revenue if they have the knowledge, the skills and the tools to handle EV charging.

In this presentation, learn about current eMobility trends as well as installation and troubleshooting solutions for level 1 and level 2 charging stations.

Register here to learn more—it’s free!

Understanding And Measuring Failure Modes In Electric Motors

Electric motors and powertrain present new challenges for durability testing. Electric motors introduce new failure modes like demagnetization, bearing currents, and inter-turn shorts, amongst others. These failures will result in mechanical failure modes but can be more easily monitored and understood through electrical measurements.

This session will discuss the failure modes of electric motors, the benefits of measuring electrical values for durability testing and give accurate data from durability testing.

Register here to learn more—it’s free!

Best In Class Stator And Rotors: Boosting Torque Density Using Magnetic Materials

Carpenter Electrification’s soft magnetic materials are advancing the performance of electric vehicles, hybrid and full electric aircraft, drones, robots, and other size-and-weight-sensitive applications.

Carpenter Electrification’s newly launched and fast-growing Motor Technology Center (MTC) is a part of the company’s multi-million-dollar investment to advance and accelerate its disruptive laminations and stacks technology.

In this session, Dr. Nir Vaks will present the state-of-the-art facility including some of its unique equipment, stack and motor testing capabilities, and overall operations. Additionally, he will demonstrate how Carpenter Electrification’s high-induction, low loss magnetic materials and stack technology is used to improve motor torque, power, and size. Discussion on the effects of stress on motor performance, the importance of stacking methods, examples of stacks created in the MTC, and future advancement will also be included.

Register here to learn more—it’s free!

How Flexible Printed Circuits Are Influencing The Electrification Road Map

Learn how Flexible Printed Circuits are disrupting the electrification technology space with innovative design for automotive quality & reliability.

The result: Optimization of cost of ownership and improved vehicle range requirements for lower weight, tighter space and automated assembly for interconnect, sensing, and thermal management applications.

Register here to learn more—it’s free!

See the full session list for the Fall Virtual Conference on EV Engineering here.

Broadcast live October 17 – 20, 2022, the conference content will span the EV engineering supply chain and ecosystem, including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection, wire and cable, EMI/EMC and more.

[ad_2]

Source link