[ad_1]

Bikerumor may earn a small commission from affiliate links in this article. Learn More

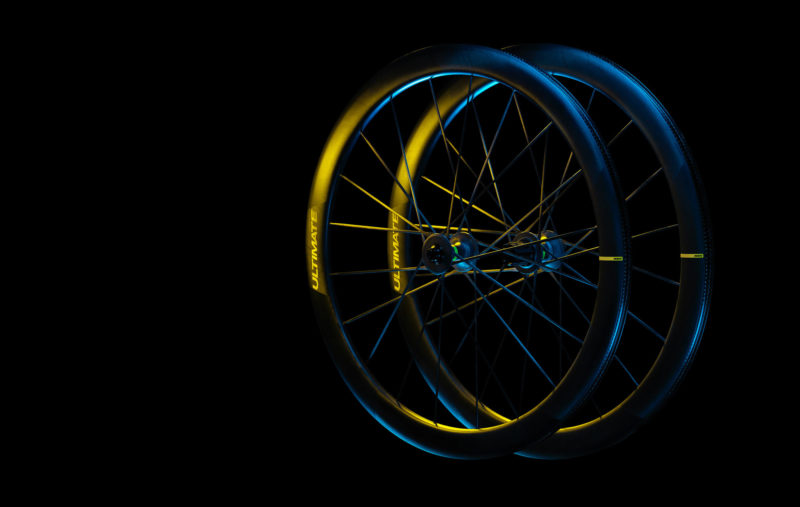

Using new technology that gets carbon to mimic some of their best alloy trickery from years past, the new flagship Mavic Cosmic Ultimate 45 road wheels achieve a feathery 1,255g weight with 45mm deep rims.

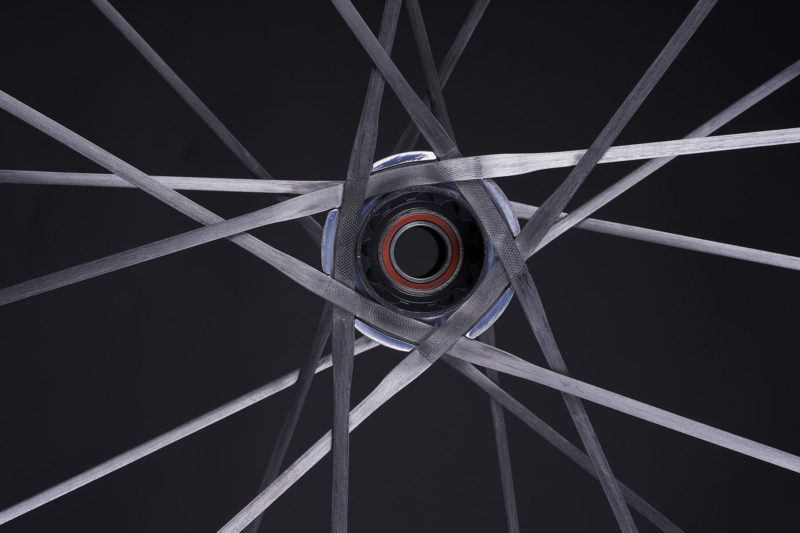

The wheels are a one-piece unit, built with pass-thru bladed carbon spokes that are bonded into the rim without penetrating the tire bed. It’s a unique construction, unlike any past effort…in carbon. Here’s how they did it…

Each wheel is hand assembled in their factory in Annecy, France, and requires 8 hours and 71 carbon pieces. While it looks like the spokes are inserted into the rim like normal, they’re actually bonded into alloy inserts using Mavic’s Fore technology.

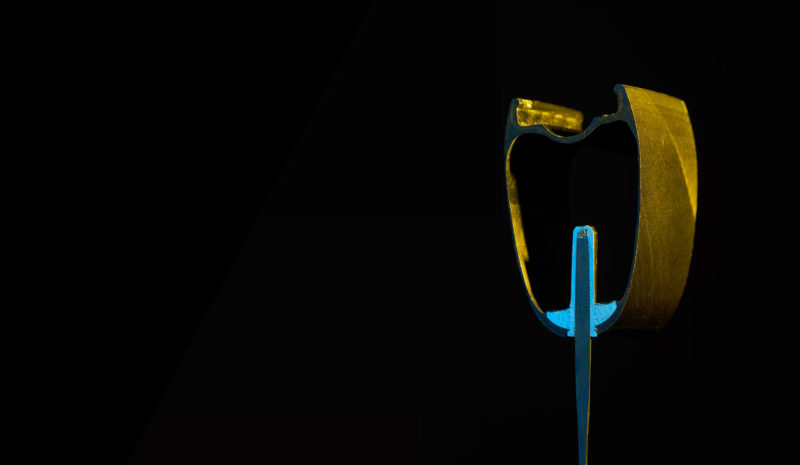

If you recall, Fore originally referred to their ability to form reinforced, threaded sections inside an alloy rim cavity. Then, the spokes were threaded directly into the rim. The spoke’s head was captured at the rim, and the oversized nipple put an end to any stripping when truing the wheel.

For carbon, they molded an alloy insert between layers of carbon, then threaded the spokes into it. Both versions eliminated the need to drill through the tire bed, making tubeless setup easier and tape-free. It also let them make a lighter wheel with laterally stiffer rims.

For the new Cosmic Ultimate 45, the spokes are molded, then bonded into the rim’s Fore inserts with the correct two-cross positioning, then that piece is heated and molded to become one.

These Fore attachments were tested. A lot. 409 impact tests. 470 traction tests. 66 prototypes, and 8 different constructions. Then they underwent the accelerated climate tests.

And it’s not just the attachments. The spokes themselves are a new R2R (Rim to Rim) UD carbon spoke thats 4x stronger than the prior generation.

From there, the hub is placed between the spokes and carbon caps are pressed into place. The wheel is heated again to mold the entire wheel into a single piece.

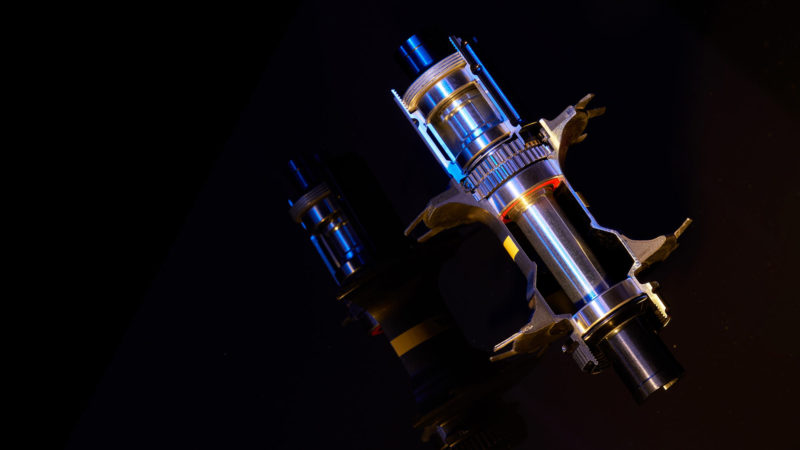

The hub has an alloy base with carbon wrap, which keeps it light but allows higher precision bearing placement. They’re oversized bearings, too, with stiff hub axles, for smoother, more durable performance. Their ID 360 internals (think DT Star Ratchet) provide quick, strong engagement.

Claimed rim weight is just 403g, which is respectable, but it’s the full carbon spokes that bring the wheelset weight down so low. That helps them spool up quickly and avoid flex, both torsionally and laterally…but still give them a bit of radial flex for good ride quality. Logos are laser etched, saving a few grams compared to decals.

Internal rim width is 19mm, and the tubeless-ready design is made for 25mm or larger tires in mind. They say the ideal tire pressure is 87psi (6bar). Maximum external width is 28mm, with a 45mm depth and wind tunnel-tested NACA profile.

Above, the glitzy quick view of how they’re made. Below, a more detailed look as they walk their athletes through the process:

Complete wheelset weight is claimed at 1255g – front is 575g, rear is 680g. They’re only available in tubeless, disc brake formats with Center Lock rotor mounts and 12×100/12×142 thru axles (Quick release and 12×135 thru axle adapters are available separately). Choose from Shimano HG, Campagnolo road or N3W, and SRAM XDR freehub bodies. MSRP is €3,999.

[ad_2]

Source link