[ad_1]

There is a wide range of characteristics that describe the performance of any given battery chemistry: energy density, specific energy, specific power, discharge efficiency, self-discharge rate, cycle life, calendar life, and—not the least important—cost.

Some types of Li-ion chemistries are really good in a few characteristics but fall short in other areas. This is particularly true of the next-gen chemistries you read headlines about. In fact, most of these new breakthrough cells are still “under development” because, while they may show excellent results in one area (like energy density, for example) researchers are still searching for ways to improve other characteristics (like specific power) to make them viable for EVs or other applications. We’ve been reading about “ultra-high-energy batteries” and “new batteries that can be charged in 5 minutes” for a decade, but those articles typically leave out the chemistry’s other characteristics, which may fall short of the requirements of EVs.

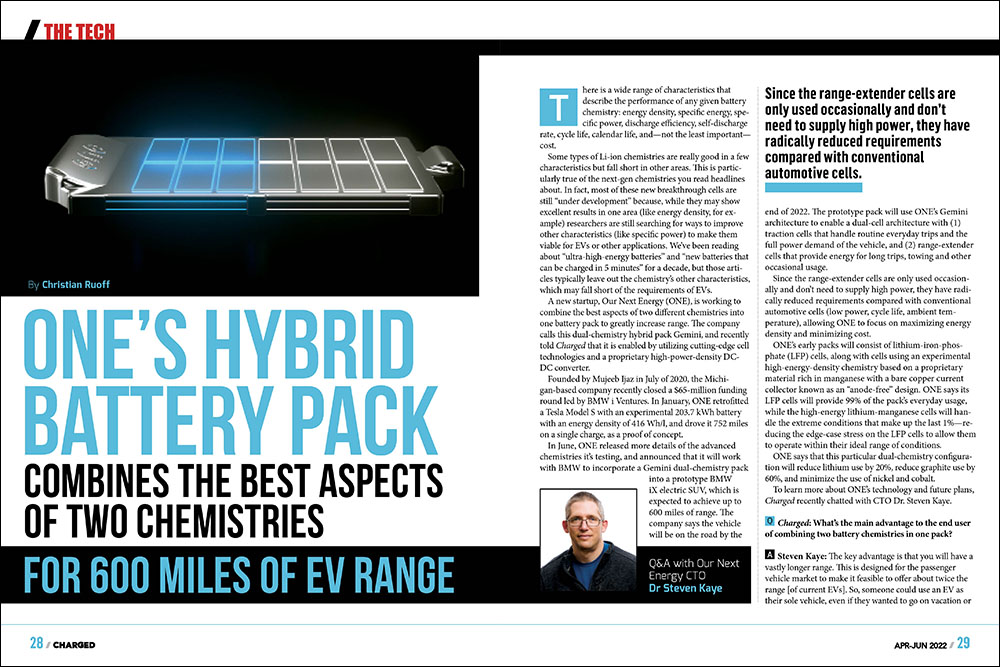

A new startup, Our Next Energy (ONE), is working to combine the best aspects of two different chemistries into one battery pack to greatly increase range. The company calls this dual-chemistry hybrid pack Gemini, and recently told Charged that it is enabled by utilizing cutting-edge cell technologies and a proprietary high-power-density DC-DC converter.

Founded by Mujeeb Ijaz in July of 2020, the Michigan-based company recently closed a $65-million funding round led by BMW i Ventures. In January, ONE retrofitted a Tesla Model S with an experimental 203.7 kWh battery with an energy density of 416 Wh/l, and drove it 752 miles on a single charge, as a proof of concept.

In June, ONE released more details of the advanced chemistries it’s testing, and announced that it will work with BMW to incorporate a Gemini dual-chemistry pack into a prototype BMW iX electric SUV, which is expected to achieve up to 600 miles of range. The company says the vehicle will be on the road by the end of 2022. The prototype pack will use ONE’s Gemini architecture to enable a dual-cell architecture with (1) traction cells that handle routine everyday trips and the full power demand of the vehicle, and (2) range-extender cells that provide energy for long trips, towing and other occasional usage.

Since the range-extender cells are only used occasionally and don’t need to supply high power, they have radically reduced requirements compared with conventional automotive cells.

Since the range-extender cells are only used occasionally and don’t need to supply high power, they have radically reduced requirements compared with conventional automotive cells (low power, cycle life, ambient temperature), allowing ONE to focus on maximizing energy density and minimizing cost.

ONE’s early packs will consist of lithium-iron-phosphate (LFP) cells, along with cells using an experimental high-energy-density chemistry based on a proprietary material rich in manganese with a bare copper current collector known as an “anode-free” design. ONE says its LFP cells will provide 99% of the pack’s everyday usage, while the high-energy lithium-manganese cells will handle the extreme conditions that make up the last 1%—reducing the edge-case stress on the LFP cells to allow them to operate within their ideal range of conditions.

ONE says that this particular dual-chemistry configuration will reduce lithium use by 20%, reduce graphite use by 60%, and minimize the use of nickel and cobalt.

To learn more about ONE’s technology and future plans, Charged recently chatted with CTO Dr. Steven Kaye.

Charged: What’s the main advantage to the end user of combining two battery chemistries in one pack?

Steven Kaye:The key advantage is that you will have a vastly longer range. This is designed for the passenger vehicle market to make it feasible to offer about twice the range [of current EVs]. So, someone could use an EV as their sole vehicle, even if they wanted to go on vacation or tow something on a long weekend with friends or family. That is one drawback that is preventing some types of buyers from going electric. The goal of Gemini technology is to enable occasional long trips without having to worry too much about mapping out where the charging stations are.

What we’re seeing in terms of technical advantage is, when we’re working with OEMs, looking at their existing packs and then swapping out for the Gemini technology, we can get about a 75 to 100% improvement in range, in the same envelope. This is possible with a hybrid pack, basically splitting up the cells—some to provide power and others to provide energy and life—and enabled by a very high-power-density DC-DC converter that we’ve developed.

Charged: How many different battery chemistries have you evaluated to combine into one Gemini pack? What makes two different cells a good match?

Steven Kaye: Right now we’re working with a graphite/lithium-iron-phosphate (LFP) chemistry that is specially designed to have a little bit higher power because it’s a smaller percentage of the overall pack. So, it’s an LFP specifically tuned for the power demand, essentially designed to meet the demands of average daily driving.

For the second chemistry, we have explored a few different options, all very high-energy. The leading candidate has to be a very high-energy cell design, like silicon, lithium metal or lithium-manganese for example. This second chemistry will be designed to maximize energy density and allow us to trade off on all the other requirements. You can think of the second group of cells as a range extender, providing more energy occasionally when needed.

Charged: So, you are looking at next-gen battery chemistries that others wouldn’t typically consider to be ready for production?

Steven Kaye:That’s correct. We’re looking at battery technologies that will work for us, but don’t yet work for anybody else. Essentially, our approach here is to try and take technologies that might be five or ten years away from production and pull them forward and use them today. So, we will need to work with materials and cell vendors to scale the technologies that they’ve got. That’s part of our roadmap.

We’re looking at battery technologies that will work for us, but don’t yet work for anybody else…that might be five or ten years away from production, and pull them forward and use them today.

Because we can reduce all the other requirements and just focus on very high energy, we can use cells that are only achieving about 200 cycles in the lab, for example. In our dual-chemistry battery pack application, the second group of cells will have no high- or low-temperature requirements, power demand will be really low, and that lets us push the energy density characteristics pretty high.

Charged: Can you give us more details about the proprietary manganese-rich material that you’ll be using with the BMW prototype?

Steven Kaye: We have three generations of anode-free technology, ranging from a version that minimizes use of nickel and cobalt to a version that’s nickel- and cobalt-free. The BMW iX demo will use generation one, [which] contains nickel and cobalt. In 2023, we expect to maximize manganese, reduce nickel and eliminate cobalt.

Charged: How does an “anode-free” cell work?

Steven Kaye: An anode-free cell is a lithium metal cell [in which] the lithium anode is created inside the cell during the formation process. A cell is built using a standard cathode material and a bare metal foil for the anode. When the cell is first charged, lithium is extracted from the cathode and plates onto the metal foil, forming the lithium metal anode.

ONE has developed a unique liquid electrolyte that improves the efficiency of the lithium plating process, improving the cell cycle life and reducing the swelling, gassing, and dendrite formation of typical lithium metal anodes.

Charged: What are the general advantages and shortfalls of that type of anode-free cell? What led you to choose this chemistry instead of others?

Steven Kaye: ONE’s anode-free cell advantages include high energy density (thin lithium metal anode), low cost (no anode present during cell assembly, low-cost liquid electrolyte), and abundant raw materials (mostly manganese, zero cobalt).

The challenge is that anode-free cells still have low cycle life. [However], this is mitigated by ONE’s Gemini architecture, which uses the anode-free cell as a range-extender, requiring only about 200 cycles. [Also, typical anode-free cells experience] cell swelling and gassing over life. This is mitigated by ONE’s anode-free electrolyte and other innovations in the pack architecture.

Charged: Your custom DC-DC converter design is a main focus of development. Can you tell us what is special about it?

Steven Kaye: We’re actively working on all the components of this [system], the main two being the DC-DC converter and the high-energy cells. There are also a lot of other components, as you can imagine—there hasn’t been a commercial dual-chemistry architecture before. There are a lot of architectural innovations we’re working on that allow us to further increase the energy density, handle the power and heat, things like that. Now we are working with BMW towards a full demo pack in a vehicle, basically the next evolution of the Tesla range demo we did in January. So, that’s our next big milestone. From there, hopefully, we’ll start working towards some production programs with excited OEMs.

For the DC-DC converter, there’s been a huge amount of innovation in power electronics and components in the last five years or so. Building off of that, we’ve been able to design something with much higher power density than any automotive DC-DC, at least that I’ve seen, and great efficiency. Essentially, getting the power density up high enough while still maintaining good efficiency that allows you to use these dual-chemistry architectures without the DC-DC converter taking up so much volume that it eats away all your advantage. This uses electronics we’ve designed ourselves and we’re having built specifically for Gemini.

The key thing here is, for passenger vehicles, 99% of daily trips are under 150 miles, but a large share of people’s purchasing decisions are driven by the need for these occasional long-duration trips or towing—think high-energy-demand use cases. So, by using the DC-DC converter, and the second high-energy chemistry behind that, we can really reduce the requirements on those range-extender high-energy cells. It lets us [eliminate] high- and low-temperature requirements, doesn’t need high power, and doesn’t need long life. That lets us use a lot of these bleeding-edge technologies, with much higher energy density. Our target is roughly double the range of existing passenger EVs, and we think [an energy density of] about 450 Wh/l will be achievable.

Charged: Your custom DC-DC design is used to shuttle energy between the two types of cells in the pack, correct? When needed the high energy pack will transfer power to the main pack, which drives the traction system, is that right?

Steven Kaye: ONE’s Gemini DC-DC can shuttle energy between the two cell types as well as from each cell directly to the high-voltage bus. The high-energy, range-extender pack can also provide power directly to the high-voltage bus, with the main pack providing peak power when needed. The full details of the DC-DC operation are not something we’re ready to disclose publicly, as it enables many of the unique features of the Gemini architecture.

ONE’s Gemini DC-DC can shuttle energy between the two cell types as well as from each cell directly to the high-voltage bus.

Charged: Will the dual-chemistry packs need a special onboard charging system?

Steven Kaye: No. There’s a single charge connector into the pack, totally standard, looks like what everyone uses today. And then our battery management system handles the distribution of power between the range extender cells and the main traction cells.

Charged: Would it make sense to use this sort of dual-chemistry pack to create low- to mid-range EVs, with a range of, say, 200-400 miles, or does the cost/benefit math only work for super-high-range 500-800-mile EVs?

Steven Kaye: Four hundred miles is pretty reasonable. We did the big demo with the Tesla, where we traveled 752 miles, just pushing the envelope as far as we could and getting people excited. I expect that you will have some premium cars with ultra-long range, but others where you don’t go near it. You’ll design it for what the customer needs for different vehicle segments. I mean, even gas cars, most of them cap out at like 400 miles.

Some people want vehicles with a really long range. Others really need that towing capacity. I can imagine for pickup trucks and things like that, what you’re really worried about is, what happens when the thing’s really loaded? So, you want to be able to have the range to handle those scenarios.

Charged: Instead of doubling the range, could you halve the pack size? Say you built a 300- to 400-mile pack, would it be half the envelope of the conventional single-chemistry technology?

Steven Kaye: I think what you’re getting at is the design trade-offs. If you fix the power, then you fix the size of the traction battery. And then the larger the vehicle is, the larger our energy density advantage is. So, you can’t just straight scale it down and expect the energy density to be the same. It does get worse, but our modeling indicates we can still stay around 400 Wh/l at a normal sedan size. If you start talking about vehicles that don’t have the power demands that a lot of premium vehicles have, then you can further downsize that traction battery and gain back some of the advantages of a dual chemistry.

For very small vehicles, this probably isn’t the best technology. But once you’re into normal family sedans, it still nets out a pretty large advantage. And then as you move to larger vehicles, like an SUV or a truck, the advantage gets quite large.

All that said, it’s hard to give single numbers as an answer to that question, but for very small vehicles, this probably isn’t the best technology. But once you’re into normal family sedans, it still nets out a pretty large advantage. And then as you move to larger vehicles, like an SUV or a truck, the advantage gets quite large.

Charged: So, basically you think it will work well for all the very popular models that Americans buy?

Steven Kaye:Yes, exactly.

Charged: You have a diverse history in the battery industry. Can you tell us what led you to ONE?

Steven Kaye: My background is in chemistry and material science. Did my undergrad at MIT and then PhD at Berkeley, pretty much all in energy technologies—solar, hydrogen storage for fuel cell vehicles.

Then out of school, I joined a startup, Wildcat Discovery Technologies, that does unique high-throughput synthesis and testing of new materials, 10 times faster than conventional labs. A couple months after I got there, they decided they wanted to start a new project in batteries. That sounded exciting to me, so I kind of raised my hand and took that on. I essentially started the battery program there. Within a couple of years, I was promoted to Chief Scientific Officer, leading both the chemistry and engineering groups. That battery project grew into what was effectively the whole business of the company, which was pretty fun. While I was at Wildcat I met Mujeeb Ijaz, who was the founder of ONE. He was at A123 at the time. We worked together on some projects, and I really liked working with him.

After Wildcat, I went and started my own company, Mosaic Materials, which was involved in gas separations. We spun a technology out of UC Berkeley, and that company actually just got sold to Baker Hughes.

At some point, Mujeeb got recruited by Apple to start a new battery organization there, and reached out to me. I joined him to lead the materials team in his organization there. We worked together for five years at Apple.

He then left to join ONE. I left a couple of months after that, to work on a COVID diagnostic project, because this was in the middle of the pandemic. Then just about three or four months ago, he recruited me to come and join ONE and start up the new R&D organization at the company.

Charged: I imagine ONE is actively hiring and building up your teams, like most of the EV industry?

Steven Kaye: Yes. When I joined, we announced that we’re putting together this Bay Area R&D facility. That’s where most of the work on the Gemini program is happening, as well as future technology development. We’ve started building out the team here and we’re hiring a ton of people this year.

We’re looking for people for pack design, mechanical design, electronics, software, cell and materials and manufacturing R&D backgrounds. Engineers, scientists, essentially all levels.

This article appeared in Issue 60: April-June 2022 – Subscribe now.

[ad_2]

Source link