[ad_1]

There are many ways to develop an e-drive system, or a vehicle with an e-drive system as the source of propulsion. Traditional development methods, while effective for some applications, also present some major challenges—especially when it comes to scalability.

Technical and non-technical issues challenge developers and manufacturers in this propulsion system development process. Factors such as thermal management, efficiency and NVH tradeoffs, control stability, and new feature sets / driving modes are just some of the technical challenges that teams face. On the other hand, there are a number of disruptive challenges like small, slowly growing team sizes, staying current in a rapidly changing industry, and an increasing number of programs and responsibilities within the companies. Each of these challenges can slow down technical efforts.

Given all the challenges, e-drive system development cannot be done quickly, efficiently, and with acceptable quality standards using just the commonly used methods and tools. Innovation of the methodology is also required. Along with traditional chassis dynamometers, powertrain testbeds, and e-motor emulators, AVL offers a number of innovative solutions to optimize the development process.

E-Motor Concept Design, Electromagnetic Analysis, and Thermal Analysis

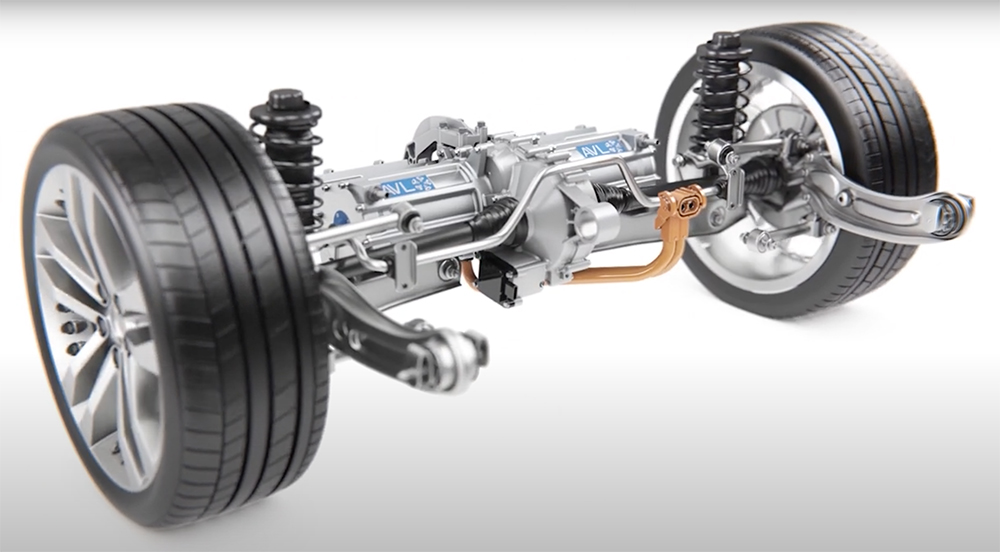

Utilizing innovative approaches, such as AVL’s e-motor tool, provides assistance for manufacturers looking for a conceptual e-motor design. Based on specific customer requirements, AVL can develop the optimal e-motor design using the latest materials and manufacturing technologies. A customized e-motor can therefore be engineered, and AVL’s reference prototype platform can support the development process.

Several key features help customers kick off the development of the e-motor design. With minimum input data, it is easy to generate e-motor variants based on basic requirements like supply voltage, torque or power inputs, and maximum speed. It is easy to customize the e-motor design and add additional constraints, such as maximum diameter, magnet type, rotor type, and lamination material.

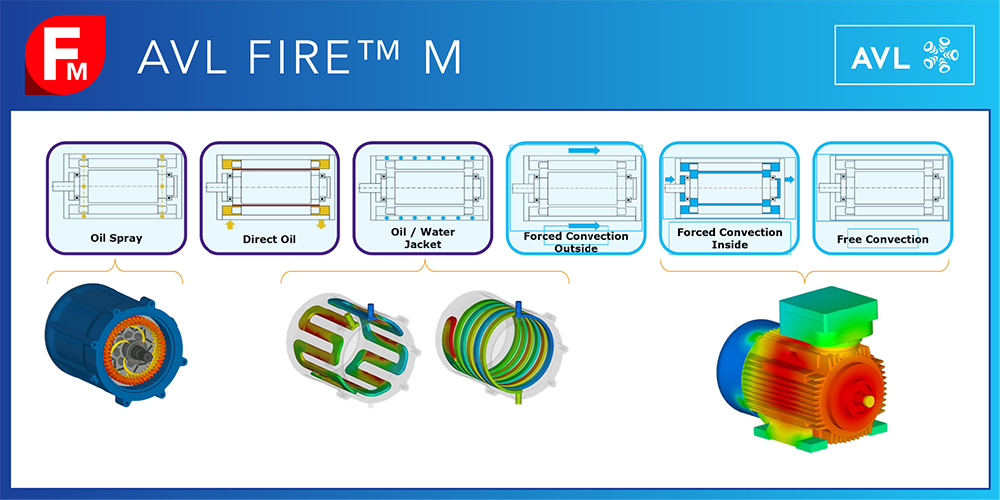

Furthermore, AVL has been able to leverage 30 years of automotive simulation experience in a unique computational fluid dynamics (CFD) simulation solution—AVL FIRE™ M—to support in the development of both conventional and electrified powertrains. FIRE M can accurately predict fluid and structure temperature distribution for all e-motor cooling concepts. The software provides analysis of flow field (flow velocity distribution and local recirculation), evaluation of pressure drop, determination of local distribution of heat transfer, and high-fidelity predictions of temperature distribution in individual components.

Optimizing Calibration Quality and Time Savings

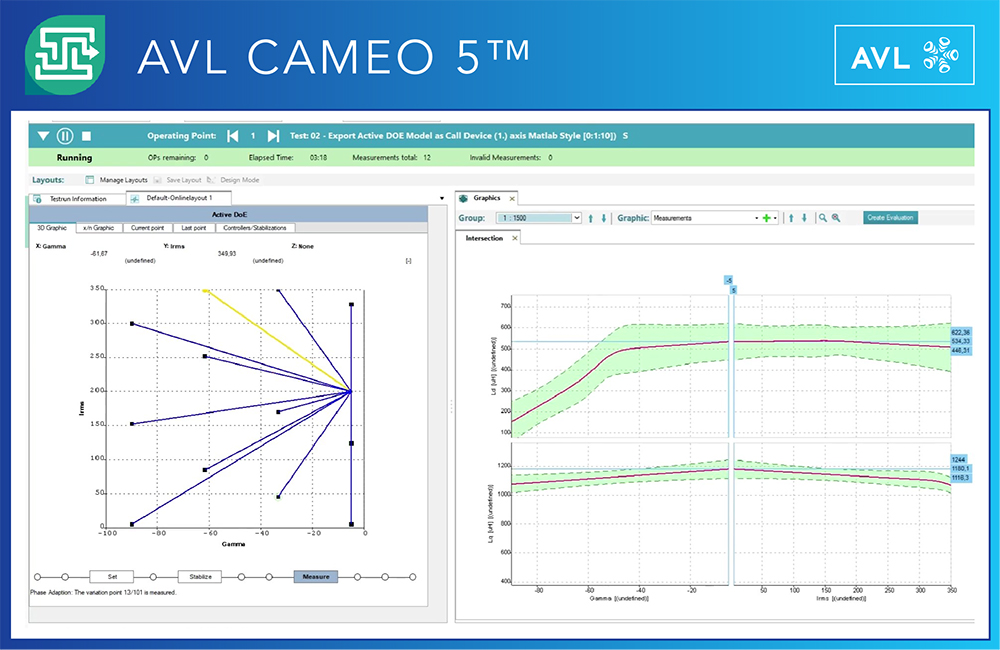

Another innovative approach to e-drive system development relates to calibration. E-drive calibration, primarily, is done manually on testbeds and takes a lot of time and effort. To achieve an efficient calibration, a lot of know-how and many activities are necessary. With functional testing and AVL CAMEO 5™ for E-Drive, customers can downsize the validation effort by setting up test cases only once. Those test cases can then be used afterwards across all environments—automated and 24/7, independent of time and location.

Powered by Artificial Intelligence, CAMEO allows users to not only perform very targeted measurements, but also simulate, optimize, and calibrate at a very early stage—regardless of the maturity level of the components. Thanks to AVL’s patented Active DoE method, a model-based simulation is produced during the test run, ready for optimization and calibration. All tests and results can be reported, shared, and discussed immediately, regardless of the personnel’s location.

Being able to easily switch between test environments and explore test cases in Software-in-the-Loop (SiL), Hardware-in-the-Loop (HiL), or on the testbed can help save up to 40% of time in the test phase. AVL CAMEO allows users to mix and match test sequences, overlap tests, and get their e-vehicle or other product on the road faster.

E-Drive System Simulation

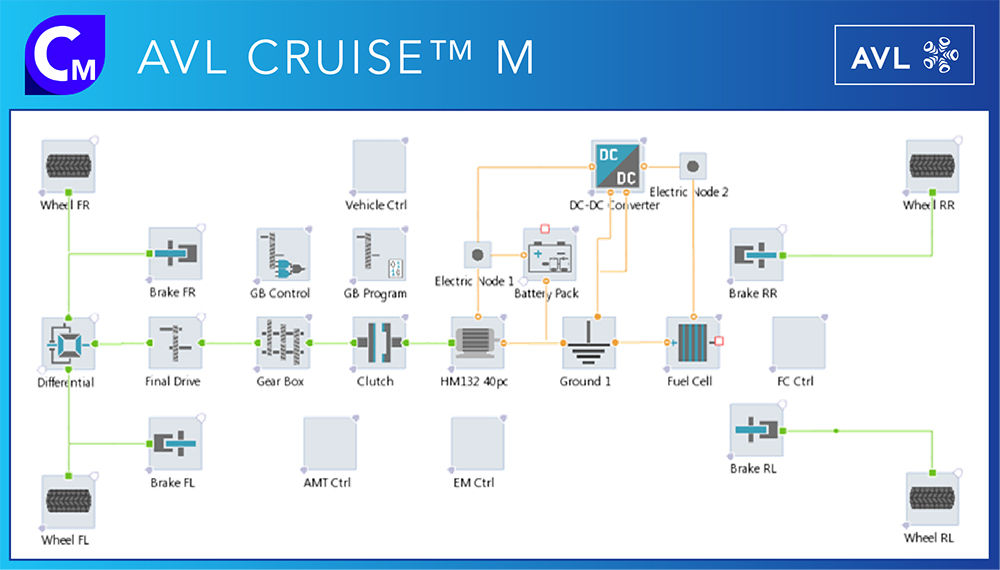

Working alongside the software solutions described above, AVL CRUISE™ M is a multi-disciplinary vehicle systems simulation tool that provides for yet another innovative way to approach and optimize electrified propulsion systems. CRUISE can be used for powertrain concept analysis, sub-system design, and virtual component integration. The software’s flexibility allows to switch easily between conventional, hybrid, and electric propulsion concepts.

Frontloading the development process is further enabled by CRUISE, as vehicle makers can predict fuel efficiency and performance early in the concept phase, even when little vehicle data is available. And one of the key benefits of the software is that office models can be used as plant models on engine, powertrain, and chassis dyno testbeds.

The AVL approach utilizing AVL CRUISE™ M is applicable over the entire engineering process and works well with third-party tools. This enables the integration in existing development environments, while saving cost and time.

World-Class Modelling Solutions for E-Motors and E-Axles

The final innovative approach to electrified propulsion system development puts the focus on NVH behavior. In pure electric vehicles, the combustion engine is not present to mask the sound and vibration of the e-motor and the transmission. These systems can generate high-frequency noise which can be uncomfortable for users, so there needs to be even more focus on NVH behavior.

AVL EXCITE™ for e-axle brings everything you need to obtain a detailed view of electrified propulsion systems into a single package and pairs it with a user interface that is intuitive for ease-of-use. With the “e-motor tool” and “e-axle tool”, the software provides a full 3D modelling environment tailored for e-axle configurations. These enable quick and easy high-fidelity modelling of interactions between electrical and mechanical systems in greater detail than ever.

With this approach, sensitivity studies can be conducted to evaluate production and assembly tolerances, focusing on design where it really matters. Investment in finding the optimum here pays off in testing and production phases and will reduce costs.

In Summary: Cost vs. Quality vs. Time

Product development follows the classical engineering model of cost vs. quality vs. time. As we move closer to type approval, the flexibility is reduced, but these points can be traded easily in early phases.

Parallel testing and CAE, increased sample numbers, and an agile testing approach with reactive changes can help reduce the amount of time. Similarly, costs may be reduced by shifting the validation focus to CAE in early phases. The application of a CAE validation process also provides for quality assurance.

Clearly, the common thread in optimizing the development process is CAE. For OEMs, the development process is essential, but also involves a huge up-front cost and risk. By using the advanced CAE tools described above, AVL can reduce these risks and efforts while also supporting better, faster product development.

From use cases, AVL workflows have demonstrated significant overall reductions in time to market and greater flexibility in the development approach, with cost savings in the region of 50% compared to OEM standard approaches. Through application of the innovative methods discussed above, the costs of such electrified propulsion system developments can be significantly reduced.

[ad_2]

Source link