[ad_1]

Battery engineers face the daunting challenge of maximizing thermal runaway protection while optimizing vehicle performance. This task becomes even more critical as cell-to-pack and cell-to-chassis designs increase in popularity because manufacturers lose the added protection that can be built into a module-based design. Although newer chemistries such as LFP and solid-state are marketed as safer alternatives to NMC, there is still a risk of thermal propagation.

Safety is a significant hurdle that automotive manufacturers must overcome to encourage the widespread adoption of battery electric vehicles. China (GB38031) and the United Nations (ECE/TRANS/180/Add.20) have set the current benchmark for controlling thermal propagation with their 5-minute delay regulations. With higher-range and higher-powered battery packs on the near horizon, OEMs should prepare themselves for subsequent regulations that will likely get longer (e.g., 10, 20, 30-minutes) until eventually, reliable non-propagating systems will be required.

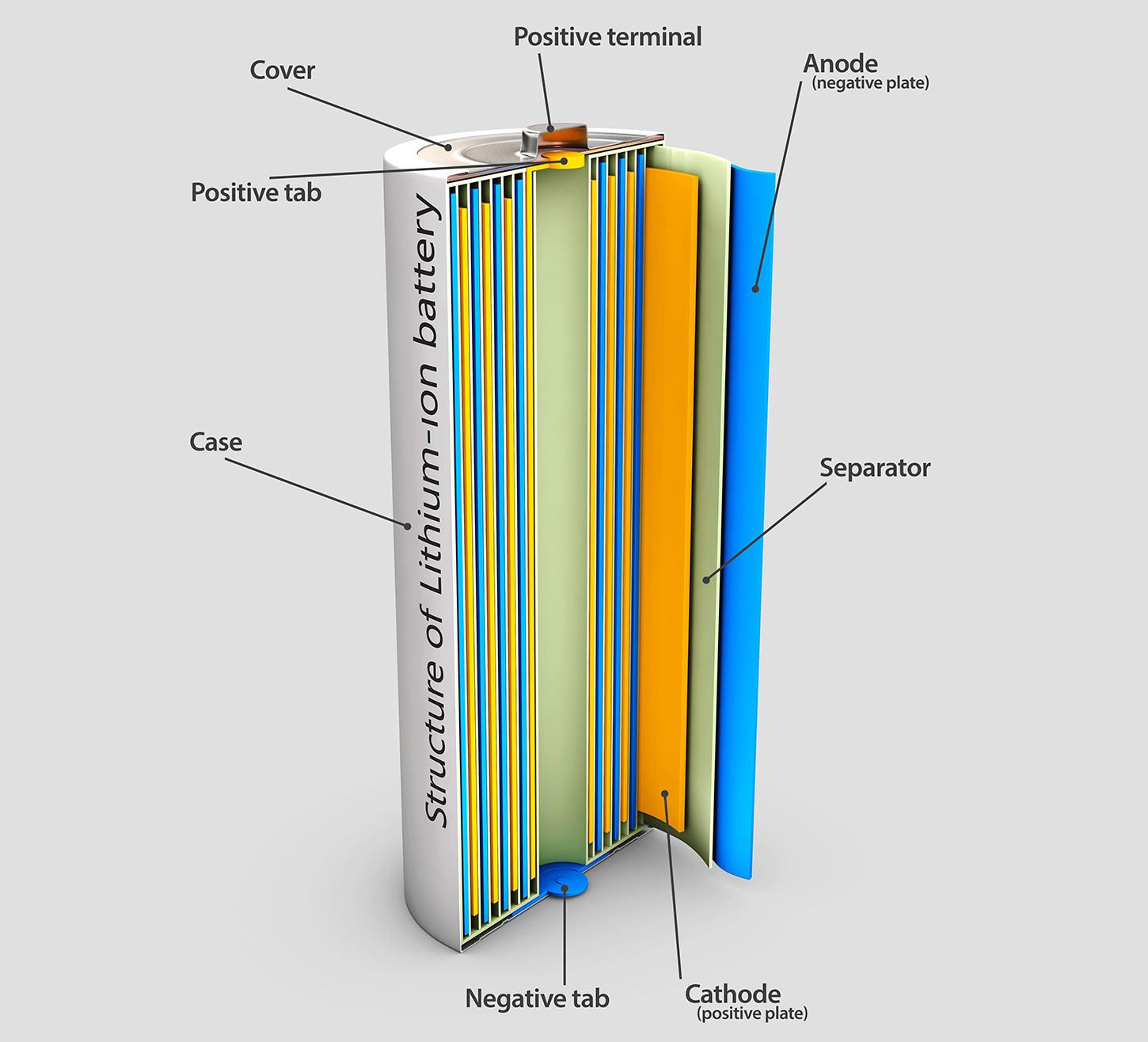

There are multiple pathways for heat to transfer from a cell in thermal runaway to its neighbors. The most obvious is cell-to-cell conduction. Other elements to consider when developing a thermal propagation mitigation strategy include gas management, secondary conductive pathways (inactive cooling plate, bus bar, etc.), and active cooling (if the mechanism is still functional after a crash scenario.) Cell-to-cell barriers are the first line of defense when trying to control thermal propagation.

Cell-to-Cell Barriers Must Manage Mechanical and Thermal Energy

In pouch and prismatic cell applications, a cell-to-cell barrier plays two roles:

Mechanical

Cell-to-cell barriers must act as a compression pad and absorb the movement of the cells as they swell with age, as well as during charge and discharge cycles. During these cycles, cells expand and contract like lungs drawing and expelling breath. Historically, this role is filled by polyurethane foams or silicone foams, but their max exposure temperatures peak at about 100 to 300°C. They are better than nothing, but will usually not meet 5-minute delay regulations.

Thermal

The second job cell-to-cell barriers fulfill is a fire barrier. They must provide exceptional thermal resistance – while compressed – at temperatures of 1000°C or higher. Materials such as metals and mica sheets perform well thermally but are limited when it comes to absorbing mechanical energy.

Aerogel is one of the few materials that can perform well in both categories. For decades, aerogel was renowned for being the world’s lightest solid and highest performing insulator but was challenging to make at scale and too fragile for practical applications. Aspen Aerogels partnered with NASA to develop and commercialize the first flexible aerogel blanket. After more than 20 years of proven success as thermal insulation, acoustic insulation, and passive fire protection in industrial applications, Aspen engineered PyroThin, an ultrathin, lightweight thermal barrier for EV applications. PyroThin thermal barriers can perform the mechanical function of a compression pad and thermal role of a fire barrier.

Global automotive OEMs choose PyroThin as part of their thermal propagation mitigation strategy because PyroThin…

Withstands Temperatures up to 1400°C

Aspen Aerogels developed PyroThin with the understanding that there is no one-size-fits-all solution for cell-to-cell barrier. Different cell chemistries burn at various temperatures, and they burn hot. PyroThin thermal barriers are a tunable platform where the aerogel chemistry and fiber reinforcement can be adjusted for an application’s requirements.

Acts as a Springy and Resilient Compression Pad

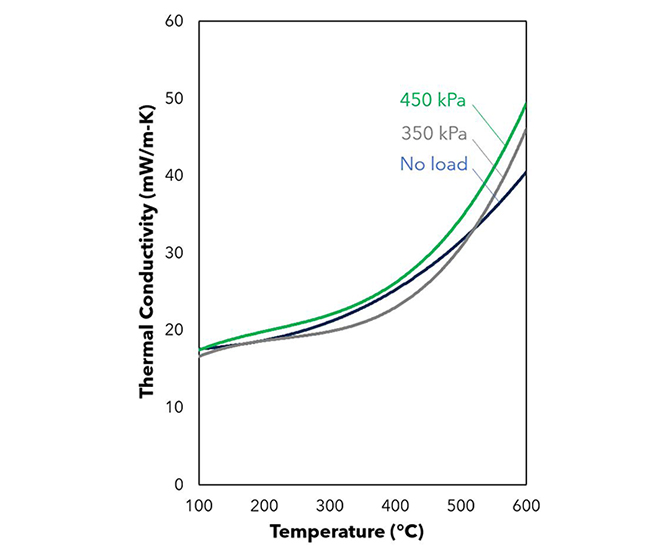

PyroThin harnesses silica aerogel’s engineered nanoporosity to deliver class-leading thermal and mechanical performance in a lightweight format. During the aerogel curing process, long silica-polymer chains are formed, and they act together as billions of elastic nano-springs. A flexible aerogel blanket has pores that are 10,000x smaller than any other insulation material. At this magnitude, the physics completely change. PyroThin has a thermal conductivity lower than still air, so when it is compressed, the thermal conductivity actually improves.

Thermal Resistance, Even When Compressed

Aerogel has the lowest thermal conductivity of any material on Earth. Unlike traditional insulations, aerogel does not rely on trapped air. When PyroThin is compressed, the air which has a lower or worse thermal conductivity than aerogel is squeezed out. This means thinner cell-to-cell barriers, more cells within modules, lighter packs, and increased range.

PyroThin Advanced Thermal Barriers Show Promise for a Non-Propagating Future

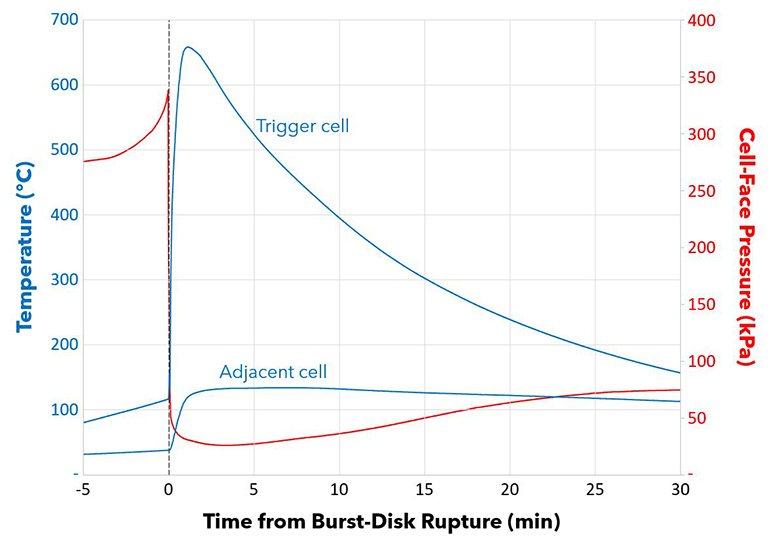

In addition to automotive OEMs subjecting PyroThin to real-world testing, Aspen Aerogels has developed a series of mini-module tests. Two cells – a trigger cell and an adjacent cell – have a PyroThin thermal barrier between them to see if it can prevent thermal propagation from one cell to the other.

In the test setup above, two 62 Ah prismatic cells (CATL) are compressed inside a jig to maintain cell face pressure. Aspen designs thermal propagation tests for end of life (EOL) pressures, so the 2.35mm PyroThin was at about 50% strain. A 160W heating pad triggers the cell into thermal runaway.

Interestingly, when the cell vents, the pressure drops, and PyroThin can slightly expand between the cells. Over the course of 30 minutes, the adjacent cell reaches a peak temperature of 130°C at the 5-minute mark but does not go into thermal runaway. It is important to note that this mini-module configuration isolates the conductive pathways from secondary pathways in an actual pack configuration. However, this testing showcases that thermal runaway can be stopped at the cell-to-cell level. Engineers can now shift their attention to the other mechanisms and how to isolate them, eventually working their way towards a non-propagating design.

PyroThin thermal barriers are a proven solution, both in laboratory settings and on the road. Aspen Aerogels was named an Overdrive Award Winner for Launch Excellence, as part of General Motors’ 30th Supplier of the Year Award. PyroThin’s technology and Aspen’s agile engineering support played a crucial role in GM’s thermal propagation strategy for their Ultium battery platform.

To learn more about PyroThin thermal barriers, visit Aspen Aerogels’ website to discuss your thermal propagation challenges with Aspen’s technical team. Or register for Aspen’s upcoming webinar – Advanced Thermal Barriers: How to Transform Your Thermal Runaway Mitigation Strategy

[ad_2]

Source link