[ad_1]

CoolMag TC is a young customer-centric organization that offers passive solutions in thermal management for EV Power Electronics. Manufacturing resins and thermoplastic compounds that offer the following advantages:

- Thermally conductive materials

- Electric isolation

- Mechanical protection

- Flame and fire protection (retardant and extinction)

Top applications for CoolMag Thermo Conductive are power transformers and semiconductors, on-board chargers (OBC), inverters and DC/DC converters, high-reliability power electronics, inter-cell coating and protection in batteries and gap filler to interface with liquid cooling in battery packs.

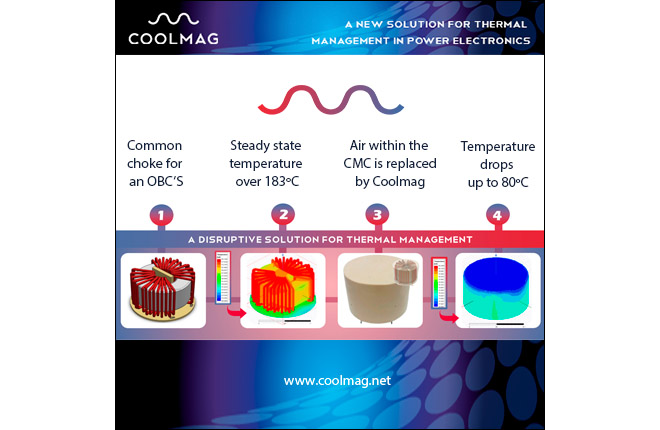

The above pictures represent (1) a Common Choke for an OBC’s (On Board Charger).

(2) The steady state temperature is so high (over 183ºC) that materials cannot support it. So, a thermal mechanism to sink the generated heat is needed.

(3) After a Coolmag 29LV (Silicone based compound) injection process, the whole CMC is encapsulated, so 100% of the empty gaps within the choke are filled with Coolmag. Thereby, air within the CMC is replaced by a thermally conductive material.

Temperature drops dramatically up to 80ºC, as Coolmag provides a great thermal coupling to sink the heat at the cooling plate.

The Benefits?

- No air, no plastics, no epoxies, no VOCS

- No magnetic striction

- No saturation of core

- No reduction of copper conductivity

- Thermal dissipation in 3D

- Fire and mechanical protection(UL 94 V0)

- High thermal diffusivity

Now, Coolmag offers an all-in-one solution called Coolmag-as-a-Service. From prototype encapsulation process to production, with final customized dispensing machines for the best product potting.

Ask for a sample!

contact us at [email protected], call +3493 480 91 87 or visit coolmag.net and/or linkedin.com/company/coolmag and ask our technicians how to improve your thermal management.

[ad_2]

Source link