[ad_1]

AM Batteries (AMB), a pioneer in lithium-ion dry-electrode technology, has closed a $25-million Series A financing round led by Anzu Partners. Other investors include TDK Ventures, Foothill Ventures, Toyota Ventures, Zeon Ventures, SAIC Capital, VinFast, Doral Energy-Tech Ventures, and Creative Ventures.

AMB will use the funding to expand its team and accelerate its commercialization efforts, advance its roll-to-roll manufacturing pilot line to a production-grade line for customers, and extend its dry-electrode manufacturing platform to new battery chemistries and technologies such as solid-state batteries.

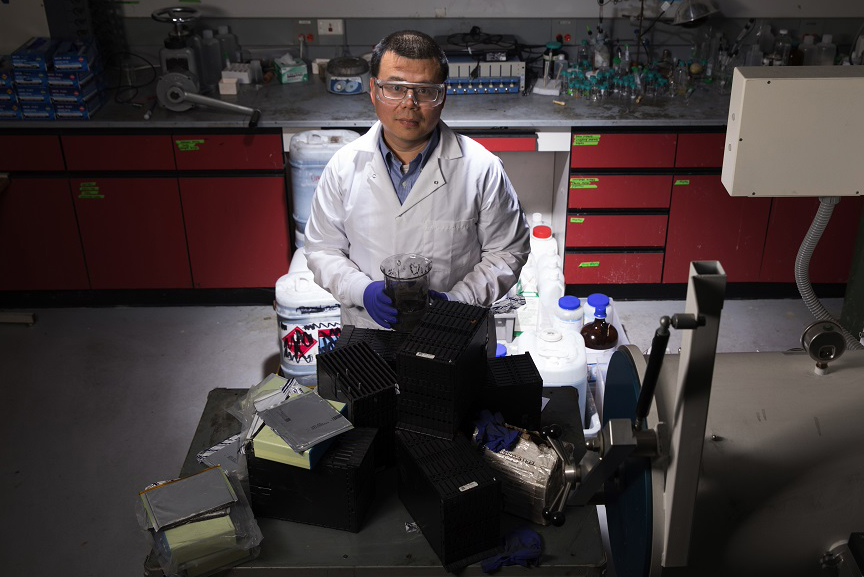

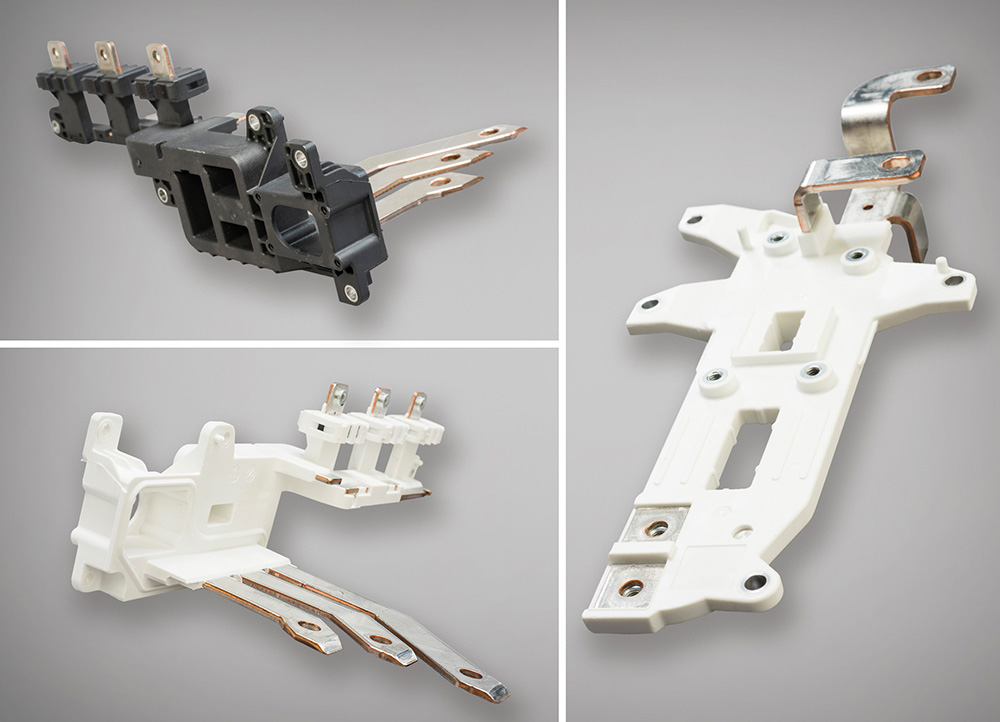

Massachusetts-based AM Batteries was founded in 2016. The company says its dry-electrode manufacturing technology allows for the coating of Li-ion battery electrodes with no need for harmful solvents or energy-intensive evaporation. Compared to the conventional slurry casting approach, AMB’s dry-electrode process “completely eliminates solvent recovery and electrode drying, which reduces energy consumption of a battery plant by 50%, saves 40% of capital equipment in electrode manufacturing and potentially produces higher-energy, faster-charging and lower-cost lithium-ion batteries.”

To manufacture battery electrodes, AMB uses an electrostatic spray deposition technique by which the cathode and anode active materials are electrostatically charged and deposited onto metal foil current collectors, which are then processed to their final state.

“One of the fundamental problems for battery manufacturers today is refining manufacturing techniques to remove the toxic solvents used in wet-coating of electrodes,” said Yan Wang, AMB co-founder and CEO. “The progress we have made at AMB is a major step forward in solving this problem.”

“EV OEMs, such as Tesla, Volkswagen and others, have already stated the need for improvements in battery manufacturing to address cost, scale and environmental impact issues,” said Jimmy Kan, Partner at Anzu Partners. “We believe the commercialization of AMB’s electrostatic spray technology will directly address these industry pain points, while providing a platform for future battery performance and safety innovation.”

Source: AM Batteries

Photo: Worcester Polytechnic Institute (WPI)

[ad_2]

Source link