[ad_1]

How to make tomorrow’s charging stations more efficient, highly reliable, and safer

Global hybrid and electric vehicle adoption depend on the network of fast-charging EV stations available. Users don’t want to run out of juice where they cannot recharge their vehicles.

Widespread adoption also depends on reducing the charging time, with the goal of getting EV charging times as close to the time it takes for a conventional fossil fuel fill-up. This requirement stipulates that high-power charging stations have more than 50 kW of charging power, and the challenge is that these types of fast charging stations are relatively more expensive.

Given the increasing importance of fast-charging stations, the demand for higher power levels, and the significant investment to deliver both, it is crucial that EV charging system designers plan for increased efficiency, reliability, and safety.

- Efficiency. DC fast charging systems must convert power efficiently. It is crucial to minimize the power conversion losses to ensure maximum power delivery for charging vehicle batteries while reducing heat buildup.

- Reliability. After installation, EV charging equipment must operate dependably for at least ten years, even in very harsh outdoor conditions, to ensure an acceptable return on investment.

- Safety. Above all else, user safety is paramount. Until recently, the public has not had access to power higher than what is available from the wall sockets in their homes. The advent of DC charging stations has changed that, making 400 to 1,000 V DC available. EV chargers must protect consumers from the threat of electrical shock and other hazards.

Efficiency

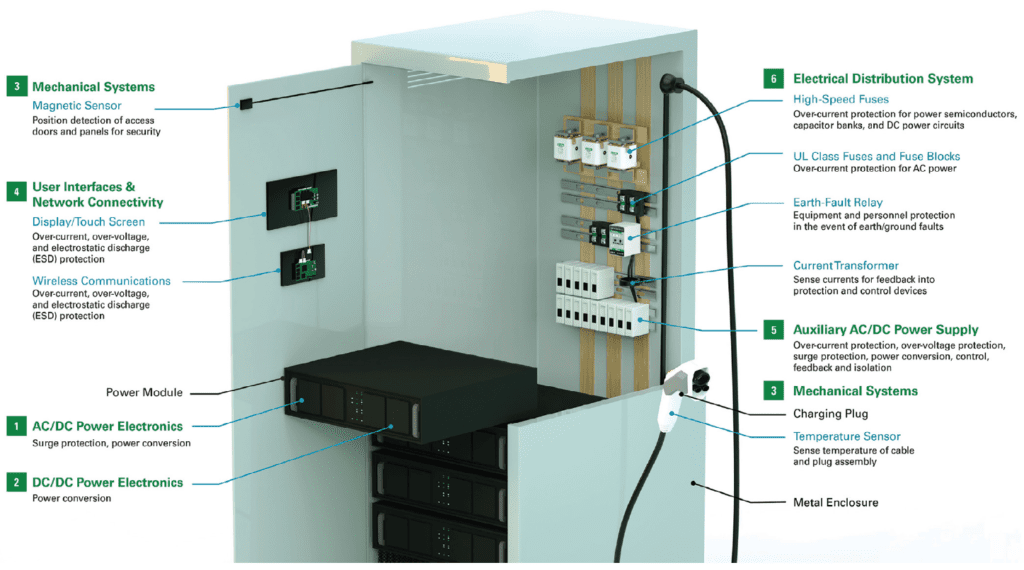

Power semiconductors convert AC power into the DC power needed to recharge a vehicle’s batteries. The power semiconductor device controls the charge by switching to match the charge level to what the vehicle battery requires, which naturally incurs power losses in the form of heat. That heat can create engineering challenges in an EV charging application.

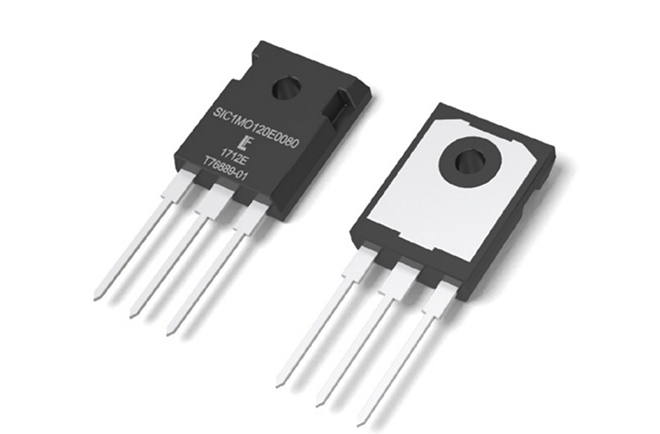

That’s why using advanced devices based on SiC and GaN technologies in power conversion makes sense; compared to silicon devices, they provide ultra-fast switching that results in lower power losses.

SiC MOSFETs blending high operating voltages and fast switching speeds are now available, a combination not found with traditional power transistors. Automobile charging applications must operate at high junction temperatures and feature low gate resistance, low output capacitance, low gate charge, and ultra-low on-resistance. Charging station designers prefer devices that offer high power density and reduce filter components’ size and weight, reducing cost and space requirements.

Reliability

DC charging stations are expensive compared to mobile devices engineered for a three to five-year lifetime, so the end-users need them to last for more than ten years to get an acceptable return on investment. Semiconductor content costs range from $350 in AC chargers to over $3,500 in a 350-kW charging system. That is why proper circuit protection is so important: it will keep the investment working reliably for a more extended period.

Semiconductors are typically fabricated from silicon or silicon carbide and have low thermal withstand capacity, thus making them very sensitive to electrical threats. They must be protected from overcurrent by fuses.

While conventional fuses can protect most devices, specialized high-speed DC fuses are required to protect the MOSFETs, IGBTs, thyristors, and diodes used in power converters (rectifiers, inverters, etc.) These fuses are engineered with a specific time-current characteristic and operate very quickly compared to traditional AC input fuses.

Overvoltage is another threat to sensitive semiconductors. For example, an EV charger near an industrial facility that uses large motors can experience voltage surges in the power supply caused by the on and off switching of those motors. Additionally, lightning strikes near the charging station result in electromagnetic energy that may induce a voltage surge on the neighborhood’s power lines that could propagate into the charger via the AC power input lines. To absorb that energy, the charging station must use overvoltage protection to prevent damage to the sensitive electronics that make the charger work.

Safety

An EV charging station’s two biggest safety threats are electrical shock and overcurrent. Electrical shock is usually the result of a ground fault.

Electrical Shock

A ground fault is an unintended contact between an energized conductor and ground or the equipment frame. Insulation breakdown is the typical culprit. Also, dust and moisture can cause unintended pathways for electricity. Wet and dusty environments, such as those found around outdoor equipment require diligence in design.

AC ground-fault protection is needed on the input side of the design to protect components from damage and consumers from electric shock should the equipment frame or housing become energized. A ground-fault protection device uses a current transformer on the phase conductors to ensure that all current coming from the source returns on those same conductors, or it reads the current in the connection between the transformer neutral and ground. A ground fault anywhere in the system will return current through this path.

Similarly, ground-fault protection is required at the output side, so that when a consumer picks up a nozzle capable of 1,000 V, the handle or the frame is not energized. A DC ground-fault monitor is installed on the output side to detect any earth leakage and shut off power immediately. As the output side is not grounded, the ground-fault monitor depends on a ground-reference module between the two buses to establish a neutral point, which is used as a reference to detect low-level ground faults.

Overcurrent

By their nature, vehicle charging stations are connected to a power supply that has high available fault current. Electrical faults, including those that start ground faults, can draw high current that can be very destructive, damaging components, twisting bus bars, starting fires, and even cause an arc-flash incident—a kind of explosion that could injure or kill anyone standing nearby.

Select fuses based on their interrupting capacity, their rating based on normal operating current, and their time-current curve characteristics. “Current limiting fuses” operate quickly in the event of a high-value overcurrent, which limits peak let-through current.

Unless interrupted quickly, even moderate overcurrents can overheat system components, damaging insulation and conductors. However, the worst damage will be to the many electronic components, which are susceptible to low-value overcurrents.

Make Circuit Protection a Forethought, Not an Afterthought, in DC Charging Stations Design

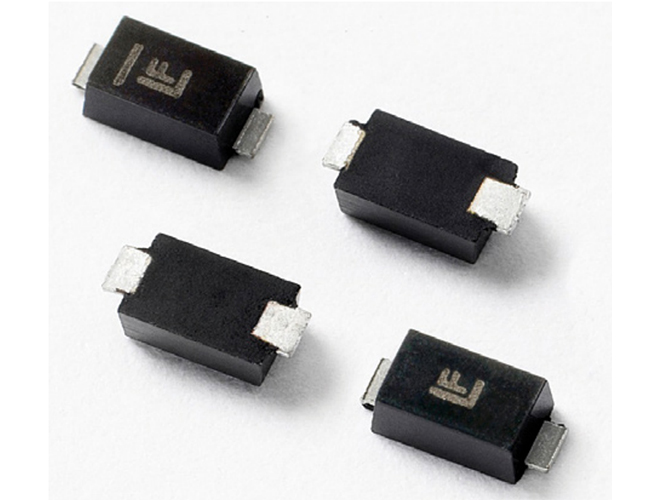

Today’s circuit protection devices encompass many different technologies, each with specific application solutions in mind. While many devices may work, selecting a component with the ideal technology for the application is better. In a DC charging system, high-power Transient Voltage Suppressor (TVS) diodes or metal oxide varistors (MOVs) typically offer the best suppression type. Other kinds of protectors—such as gas discharge tubes (GDTs), protection thyristors, and multi-layered varistors (MLVs) or combinations of suppression devices — are often specified.

When protecting sensitive circuits, it is essential to know the time a transient suppressor requires to begin functioning. For example, if the suppressor is slow-acting and a fast-rising transient appears in the system, the voltage across the protected load can rise and cause severe damage before the suppression can kick in.

Download the Littelfuse Supercharged Solutions for EV Charging Stations Guide from TTI to learn more.

Find your Littelfuse eMobility Product Solutions from TTI.

[ad_2]

Source link