[ad_1]

Oceangoing ships, most of which are powered by heavy fuel oil, produce substantial amounts of CO2 and nitrogen oxide emissions. However, shipping companies are unlikely to begin electrifying them until the economic case for doing so becomes clearer.

A new study from the University of California, Berkeley and Lawrence Berkeley National Laboratory indicates that nearly half the world’s fleet of container ships could be cost-effectively electrified, using current technology.

“We describe a pathway for the battery electrification of containerships within this decade that electrifies over 40% of global containership traffic, reduces CO2 emissions by 14% for US-based vessels, and mitigates the health impacts of air pollution on coastal communities,” write study authors Jessica Kersey, Natalie D. Popovich and Amol A. Phadke.

For the new study, which was published in the journal Nature, the research team modeled a wide variety of container ship sizes, in the context of 13 major world trade routes.

“Past studies on ship electrification have relied on outdated assumptions on battery cost, energy density values and available on-board space,” write the researchers. “We show that at battery prices of $100 per kWh, the electrification of intraregional trade routes of less than 1,500 km is economical, with minimal impact to ship carrying capacity.”

The study found that electrified container ships have an economic advantage over legacy vessels, even when the environmental and health costs of fossil fuel-burning ships are excluded. According to the researchers, the environmental and health damage caused by ICE containerships amounts to at least three times the running costs. “Including the environmental costs increases the economical range [of electrified ships] to 5,000 km,” note the researchers. They estimated the environmental and health footprint of an electrified ship at around 1/12th that of an ICE ship.

Expected future advances in battery technology will greatly increase the number of routes that can be economically served by battery-electric ships. “If batteries achieve a $50 kWh price point, the economical range nearly doubles,” the researchers write. In a few years, as the costs of large ICE container ships continue to rise, as electrified alternatives become increasingly cost-effective, running on fossil fuel could become vastly more expensive.

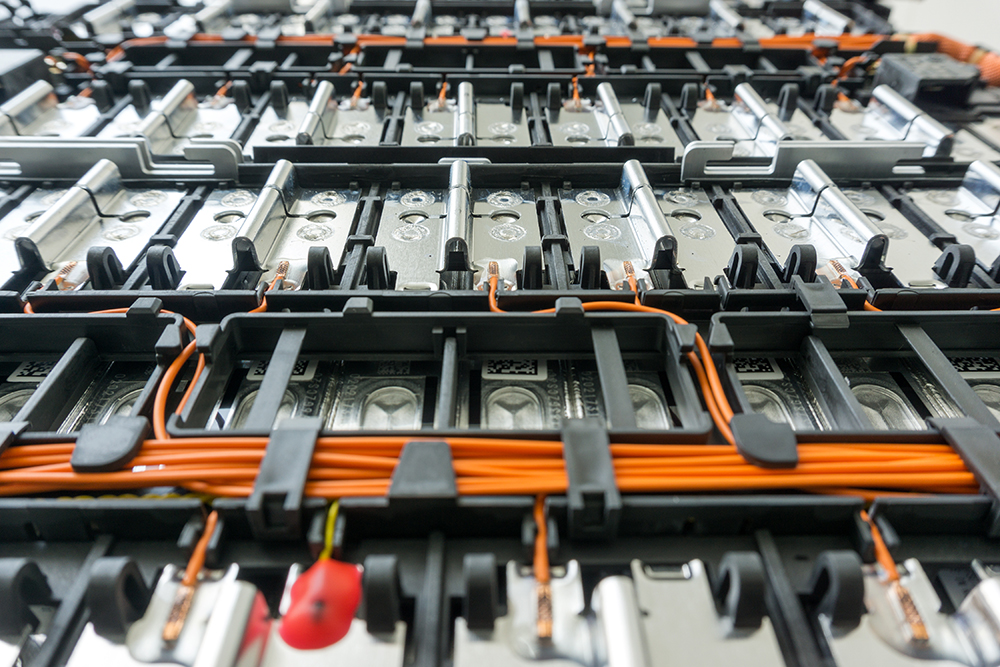

As is the case with road vehicles, different nautical use cases might be best served by different battery chemistries. Vessels that serve short routes require less power, but need to recharge quickly, so an LFP chemistry, which offers fast charging rates and long lifetimes, might be the best choice. Long-range ships typically spend a long time in each port, and could benefit from the higher energy density of NMC batteries.

The size and weight of battery systems are not trivial considerations. A container ship serving a 5,000 km route would require approximately 6.5 GWh of battery capacity. For a ship with a 20,000 km range, the batteries and motor would require 32% of the ship’s carrying capacity, or 2,500 twenty-foot equivalent units (TEU).

“The key technical constraint for battery-electric container shipping is the volume of the battery system and electric motor relative to the volume occupied by a vessel’s existing engines, fuel storage and mechanical space,” write the researchers. However, they found that “as carrying capacity increases, the percentage of total carrying capacity volume occupied by batteries decreases, because larger ships typically have lower energy requirements per unit of carrying capacity.”

A Neo-Panamax container ship serving a route of less than 3,000 km would actually require less space for batteries and motors than the volume currently occupied by combustion engines and fuel tanks.

As for the infrastructure required to charge such gargantuan batteries, the researchers predict that it will be affordable, due to dynamics of typical ports. Most berths are occupied more than 50% of the time, and at 50% utilization, the study’s model indicates that the levelized cost of a 300 MW charging station would be approximately $0.03 per kWh.

Source: pv magazine

[ad_2]

Source link