[ad_1]

Sponsored by Indium Corporation

The e-Mobility Landscape

Multiple new EV-only automakers have emerged in recent years—due in part to lower cost of entry, climate change, and environmental government policies—creating a demand to launch new competitive EVs that didn’t exist within the legacy original equipment manufacturer (OEM) marketplace. In this rapidly expanding EV market, reliability and reduced time to market will take the front seat as key differentiators between the many product offerings now available from EV start-ups and legacy manufacturers.

https://www.youtube.com/watch?v=UYkveKD00zM

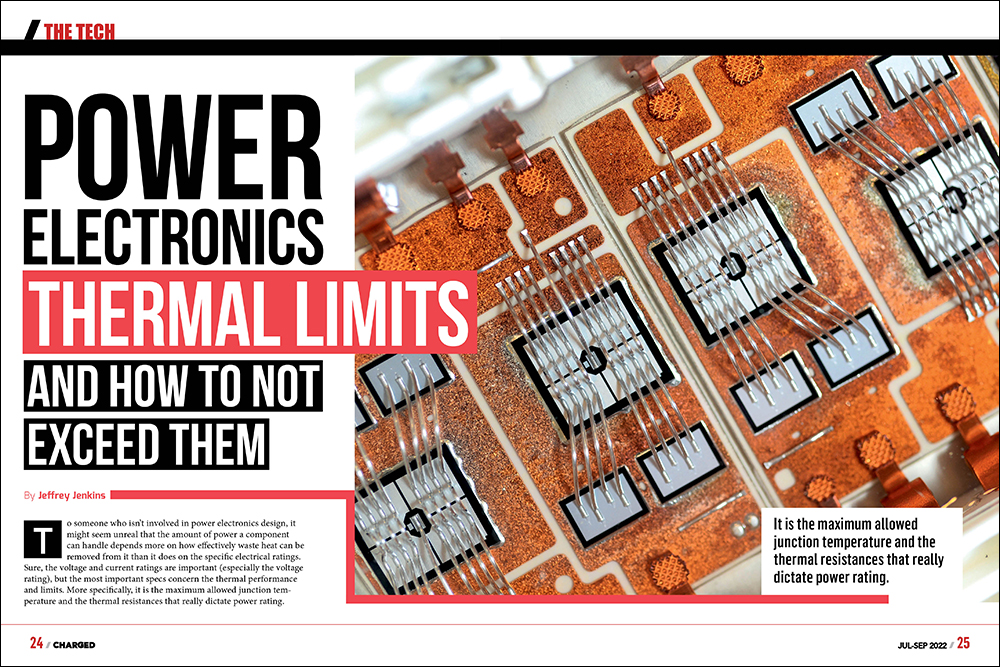

Increasing Electric Assembly Challenges

Electrical, mechanical, and thermal stresses can negatively impact the performance of the final product and, with electric vehicles, the challenge is even greater. Requirements are more demanding for high-power electric engines which run almost non-stop between charging and driving cycles, along with myriad connected electronics within the car. Even the smallest dendritic growth can shut down an entire vehicle.

Indium Corporation® is more than a materials provider—they work with customers to optimize and customize their procedures. Below are common challenges within EV electronics assembly and how Indium Corporation’s Rel-ion™ suite of award-winning products can effectively eliminate or reduce defects such as dendritic growth, voiding, head-in-pillow, and cracking.

- Electrical

- Dendrites and Corrosion – Meets stricter surface insulation resistance (SIR) with rework solutions to pass SIR unheated

- Electrical Continuity – Eliminates non-wet opens and head-in-pillow defects

- Leakage Current – Contains low Alpha particle solution for >650-volt GaN dies

- Mechanical

- Solder Delamination – Provides precision bondline control, increased creep resistance, and increased fatigue resistance

- Longer Mission Profiles – Shows increased operating temperatures and longer thermal and power cycles

- Thermal

- Hot Spots – Reduces voiding, increases CPU/GPU thermal requirements, and provides materials for power modules, IGBT, and DSC modules

Reliable, Scalable, Proven Solutions

The industry is looking for solutions that can help bring products to market faster and without recalls. Along with the development of industry standards, the use of proven products backed by expert knowledge and experience is a key component to success. Over two million electric vehicles are currently on the road with Rel-ion™ products because they are specially engineered to meet three vital criteria.

First—they’re reliable. They are designed with higher quality standards that meet the evolving demands of automotive electrification. Second—they’re scalable. They are readily available and capable of meeting supply chain expectations. Third—they’re proven. Most Rel-ion™ products have been used in EV manufacturing for more than a decade.

Rel-ion™ materials deliver reliability to EV modules, components, and systems, such as:

- ADAS

- Autopilot

- Battery Cells

- Battery Management Systems

- DC-DC Converters

- DC Fast Charging (DCFC)

- Energy Storage

- IGBT

- Infotainment

- Inverters

- On-Board Battery Chargers

- Power MOSFET

- Telematics (tcu)

Additional Resources

If you are looking for expert insight on the rapidly evolving EV market, Indium Corporation is proud to offer two free channels shedding light on both the technical challenges facing the industry, as well as the business side of e-Mobility.

Technical Insights

For expert technical insight on the challenges present in the rapidly evolving electric vehicle market, including how to ensure electrical, mechanical, and thermal reliability, check out Driving e-Mobility: Rel-ion™ Technical Webinars. These unique sessions, offered as part of Indium Corporation’s popular InSIDER Series of webinars, are led by global industry technical experts in advanced materials and the automotive market. Register for upcoming webinars or access the on-demand archive at no cost at https://www.indium.com/corporate/media-center/webinars/rel-ion.php.

Business Insights

EV InSIDER Live, driven by Indium Corporation, is a webcast series co-hosted by Brian O’Leary and Loren McDonald. Conducted in an approachable, conversational format suitable for business executives, casual observers, and seasoned engineers alike, EV Insider Live sheds light on the most pressing business issues facing the e-Mobility industry. O’Leary and McDonald are joined by a different high-profile guest from the EV industry on each episode. Register for upcoming webcasts or access the on-demand archive at no cost at https://www.indium.com/corporate/media-center/webinars/ev-insider.php.

To learn more about Indium Corporation’s suite of proven products for EV and other automotive applications, visit indium.com/relion.

Sponsored by Indium Corporation

[ad_2]

Source link