[ad_1]

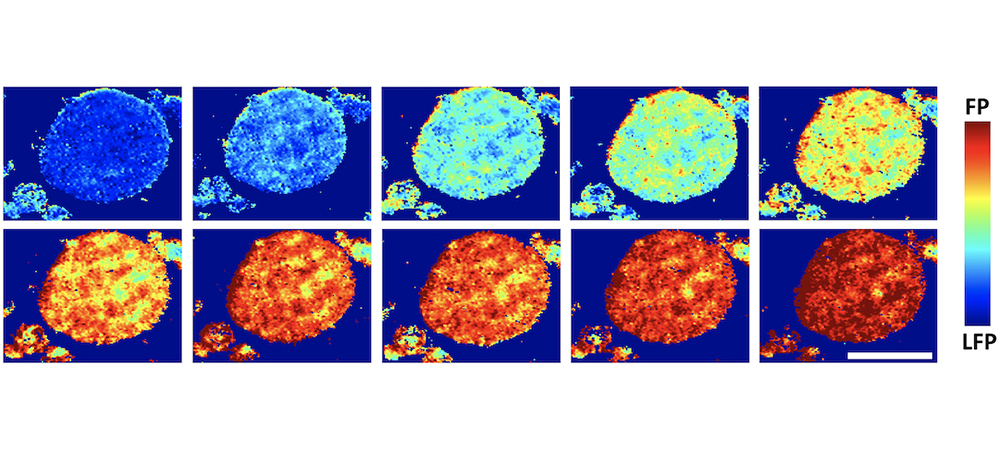

Researchers at Rice University have found that stress between misaligned crystallites in cathodes limits the flow of lithium.

In an article published in ACS Energy Letters, the researchers write: “As an important battery cathode material, reaction distribution in lithium iron phosphate (LiFePO4) has been extensively studied in dispersed particle systems, but remains poorly understood for mesoscopic agglomerates (or secondary particles) that are used in most commercial batteries.” To understand how these particle agglomerates react with lithium, the researchers relied on the transmission x-ray microscopy capabilities at Brookhaven National Laboratory and Argonne National Laboratory to produce 3D images of cathodes charging and discharging.

According to Rice News, the researchers found that “stress between misaligned crystallites in the particle agglomerates prevents lithium from being uniformly inserted into or extracted from the aggregate surface because that will generate too large an energy penalty.”

The uniformity of the lithium, in turn, affects battery charging. “In general, we always want a more uniform reaction so we can charge the battery faster,” said Rice University researcher Ming Tang.

“Introducing some porosity in the particle agglomerates might sacrifice some energy density, but at the same time would allow lithium to go in more uniformly,” said Tang. “That could allow you to get more energy at a given charge/discharge rate. Another thought is if we can somehow align the orientation of these small particles so their maximum expansion is perpendicular to each other, they’ll better accommodate lithium intercalation.”

Source: Rice News

Image courtesy of the Mesoscale Materials Science Group

[ad_2]

Source link